Our Product

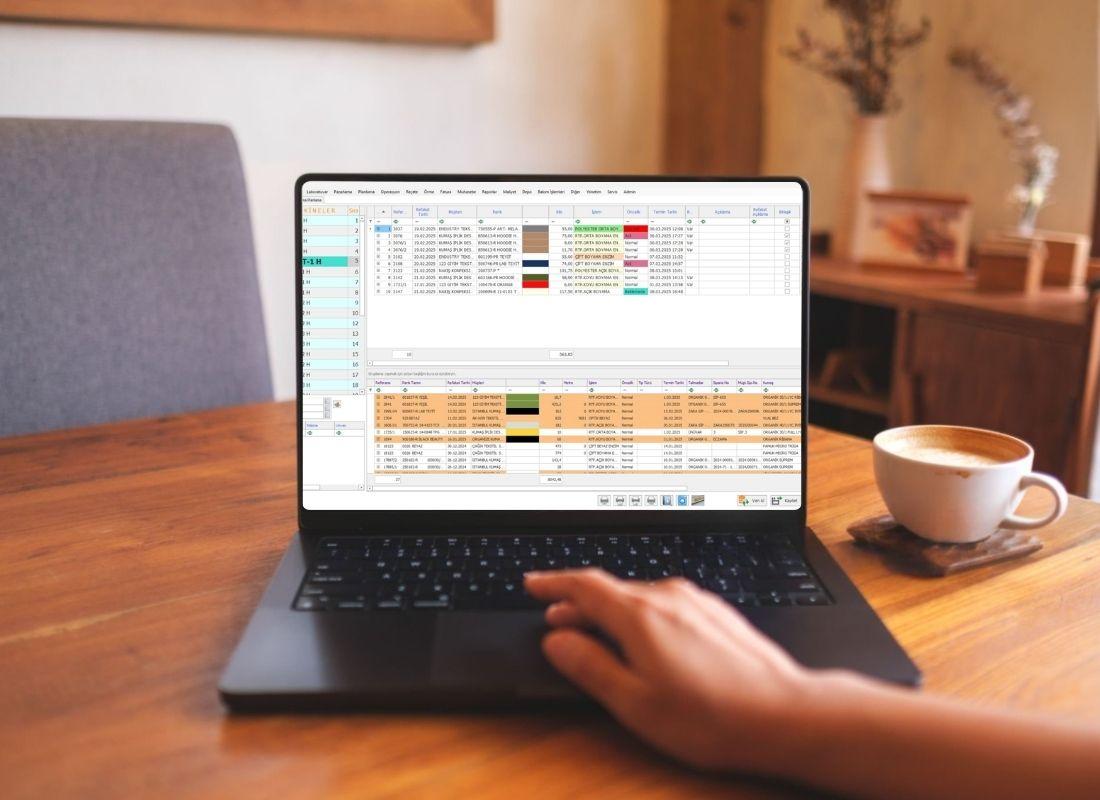

Apparel Production Tracking ERP Software (Ak-Win Q)

Marketing

Order Entries:

The model information requested by the customer is recorded into the system under order entries. The required fabric information, accessories to be used, color-size distribution, technical definitions, production criteria, loading information are recorded by selecting the model within the order. The order form is automatically sent via email to the relevant personnel within the company. Based on this information, the required fabric and accessory needs are calculated. The relevant personnel initiates the production process for order purchasing operations.

Purchasing and Supply Chain Management

Purchase Requests:

Company personnel notifies the purchasing department of any need by creating a purchase request through this module.

Purchase Quotation Requests:

The purchasing department can select the desired requests from the screen and create requests for multiple vendors. The created request forms are automatically sent to vendors as emails. The purchasing personnel can see the required raw fabric or yarn needs based on fabric orders and request quotes from multiple vendors regarding this.

Purchase Orders:

Stock orders are created for vendors, either linked to a purchase quotation request or independently, and the created form is sent as an email. When an order is placed linked to company requests, it is tracked whether the requests are met. Stock entries are made with material receipt, and the fulfillment and closing statuses of the placed purchase orders are also monitored.

Fabric Production Management

Ak-Win has two different fabric production tracking processes, detailed and simple. In the first process, production processes that take place in a simple structure, and in the second process, production processes that take place in a more professional logic are entered into the system. In both processes, the material quantities in the warehouse, production, subcontracting, or dyeing facilities are seen on a single screen. At every stage of the fabric production process, it is tracked where the yarns and fabrics have gone through which movements, consumption and waste quantities. When a price is entered into the movements and invoiced, a debit or credit record is automatically created in that company's current account. All shipment processes work integrated with the E-Waybill system, and the waybill information is sent to gib.gov.tr, and a QR code e-waybill printout is automatically taken and printed.

If desired, the production process is completed with just a few steps, and the shipment to sales or cutting is carried out. Now, let's take a closer look at all the production processes within Ak-Win.

Material Receipts:

Yarn or fabric entries that come linked to an order or independently are made. In order-linked records, order quantities are tracked. In the same slip, the shipment to production or subcontracting is also carried out. When a price is entered and invoiced, a credit is recorded in the vendor's current account.

Shipments to Production-Subcontracting:

The yarns in the warehouse are shipped to the workshop or subcontracting for knitting or weaving processes. Material shipments from the vendor to subcontracting or production are also made without going through the warehouse on the material receipt screen. An E-Waybill printout is taken.

Knitting Instructions:

If desired, knitting instructions are created to create a work order for the workshop or to give instructions to subcontracting. The desired fabric information, quantity, width, grammage, gauge, fine, etc. information are recorded and sent to the relevant personnel via automatic email.

Arrival from Production-Subcontracting:

After the sent yarns become fabric, they are received into the warehouse through the arrival from production process. Simultaneously, yarn reductions are performed in the workshop or subcontracting, including waste. If desired, they are also shipped to the dyeing facility with the same record. When the knitting or weaving labor unit price is entered and invoiced, a credit is recorded in the subcontractor's current account.

Knitting Production Tracking:

Detailed knitting production tracking can be done by entering information into the system with two different production methods, machine-based and roll-based, as desired.

The daily produced fabric information on a machine basis is entered into the system based on knitting instructions. With the record, yarn reduction is performed from the workshop, and raw fabric entry is automatically made into the warehouse.

Again, by selecting the machine, the weight, length, width, grammage, and error information of each roll are entered into the system on a roll basis. Unlike machine-based production, since the system entry is roll-based in this option, a packing list is taken at the end of the batch, and the used yarns are automatically reduced from the workshop stock, including waste. The produced raw fabric is automatically included in the warehouse without needing any further processing.

Shipment to Dyeing Facility:

Shipments of the fabrics in the warehouse to the dyeing facility are carried out for processing. If desired, fabrics produced in the workshop or subcontracting are shipped to the dyeing facility within the arrival slip without being received into the warehouse. An E-Waybill printout is taken.

Dyeing Facility Instructions:

If desired, dyeing facility instructions are created to give instructions to the dyeing facility. The quantity, color, pattern, width, grammage, shrinkage, and processes to be performed are specified for the desired fabric. It is recorded and sent to the relevant personnel via automatic email.

Dyeing Facility Tracking:

When the relevant company is selected on the dyeing facility screen, the remaining fabrics there are shown. The fabric to be processed is selected, and the incoming fabric information, color, pattern, width, grammage, batch number, gross-net quantities are entered. While the gross quantity decreases from the stock in the dyeing facility, the net quantity is included in the warehouse. The incoming net quantity, consumption quantity, and waste are also seen on the main stock tracking screen. Again, when the dyeing, printing, etc. price is entered and invoiced, a credit is recorded in the dyeing facility's current account.

Quality Control:

Fabrics coming from the dyeing facility or subcontract

Quality Control:

The fabrics coming from the weaving are subjected to quality control when necessary. Any defects in the fabrics that pass the quality control on a roll basis are recorded in the system, weight information is automatically obtained via a scale connection, labels are printed on a roll basis and placed on the rolls. A packing list is taken, and the batch is closed. The net amount passing quality is added to the warehouse.

Shipment to Dyehouse:

Fabrics in the warehouse are sent to the dyehouse for processing. If desired, fabrics produced in the workshop or externally can be sent to the dyehouse without being entered into the warehouse, with the arrival receipt. An electronic invoice (E-Invoice) output is taken.

Dyehouse Instructions:

To give instructions to the dyehouse, a dyehouse instruction is created. For the specified fabric, the required quantity, color, pattern, width, grammage, shrinkage, and processes to be performed are specified. It is recorded and sent to the relevant parties via automatic email.

Dyehouse Tracking:

When the relevant company is selected on the dyehouse screen, the remaining fabrics are displayed. The fabric to be processed is selected, and fabric information such as color, pattern, width, grammage, batch number, and gross-net quantities are entered. The gross amount is deducted from the dyehouse stock, while the net amount is added to the warehouse. The net amount, consumption, and waste are displayed on the stock tracking main screen. Additionally, the dyeing, printing, etc. prices are entered, and when invoiced, the credit is recorded in the dyehouse's account.

Quality Control:

Fabrics from the dyehouse or external sources are subjected to quality control when necessary. Any defects in the fabrics that pass the quality control on a roll basis are recorded in the system, weight information is automatically obtained via a scale connection, labels are printed on a roll basis and placed on the rolls. A packing list is taken, and the batch is closed. The net amount passing quality is added to the warehouse.

Sales:

The finished fabrics produced in the dyehouse are shipped to the customer via the sales process. The sale of raw fabrics or yarns can also be performed. An electronic invoice (E-Invoice) output is taken, the price is entered, invoicing is done, and the customer's account is debited.

E-Invoice System:

For all shipment transactions, there is an e-invoice option. If desired, the carrier, driver, and license plate are entered, and the information is sent as an invoice to gib.gov.tr, and the barcode e-invoice output is automatically generated and printed.

Reporting:

You can access the desired information at each stage of production through entry screens, and you can also monitor this information through reports.

Garment Production Management

Cutting Work Orders:

A work order is created for the cutting department. Cutting instructions are given along with the fabric and pattern information to be used for the specified order.

Pattern Reports:

After cutting, the information of the pieces cut is entered into the system based on color, size, and quality.

Classification:

After the pattern report is entered, the quantities of sizes obtained by combining the cut pieces are entered into the system. The 1st quality, 2nd quality, and damaged quantities are entered into the system, and the semi-finished size quantities are added to stock.

Production Tracking:

After cutting, the production processes are tracked via the production tracking option. The quantities that leave the department are automatically included in the next department's stock. The relevant department tracks its own production process.

Quality Control and Packaging:

After production, the control process and packaging information are recorded, and the finished products are added to the warehouse.

Loading

Sales:

The finished products received in the warehouse are shipped via the sales method, and an invoice is generated. When the entire order is shipped, the order is automatically closed.

Cost

The costs incurred during the production phase are reported through the relevant reports. They are compared with the sales price, and profit and loss calculations are made.

Pre-Accounting Module

Production Invoices:

The issued delivery notes can also be invoiced through Ak-Win. Since the invoice and price information are already available on Ak-Win, invoicing from Ak-Win is effortless and error-free. Based on parameters, invoicing is automatically done using gross or net quantities, or per kilogram or meter. The invoices issued are integrated into the accounting program.

Other Invoices:

In addition to production invoices, goods and service sales invoices and purchase invoices can also be entered into Ak-Win, and the system will automatically process them into the relevant accounts.

Accounts Receivable:

The amounts from purchase or sales invoices entered into Ak-Win are automatically transferred to the accounts receivable. When you take a detailed account statement, the content of the sales invoice is also displayed in detail under the invoice line. It works integrated with the cash, bank, and check modules. You can also manually enter information into the accounts. You can track accounts in TL or foreign currency. You can also view account statements and reports in TL or foreign currency.

Cash:

You can track all of your cash movements on the cash screen. You can enter cash inflows and outflows from accounts receivable or bank accounts on the cash screen, and these will be automatically reflected in the relevant accounts or bank accounts in Ak-Win. Foreign currency transactions can also be entered, and you can view cash balances in TL and foreign currencies.

Bank:

You can also enter and track all your bank movements in Ak-Win. These movements will work integrated with the cash and accounts modules.

Checks:

You can enter checks received from customers or checks issued into Ak-Win and integrate them into accounts receivable. You can also process the other movements of the checks, such as endorsement, bank withdrawals, collections in cash, returned checks, and others, and use them integrated with the accounts.